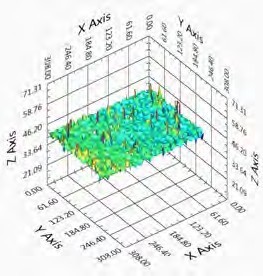

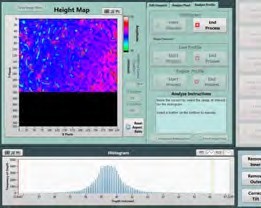

3D Measurement

Intel has accepted Optoniks 3D measurement product for socket measurement. The product stands out for its ability to effectively measure shadows and dark/ shiny surfaces. Optoniks is already working with a production line integrator to use the product on high-end components requiring 100% quality control, serving Intel’s supply chain and elsewhere.

Non-Destructive Measure

Non-Contact and No-Coating are two aspects of Optoniks’ 3D profilometry system that makes it a Non-Destructive Measurement (NDM) metrology tool.

3D Shadow Removal™

Optoniks has developed a technique based on multiple camera angles to effectively remove errors in profile measurement due to obstruction of light at particular locations.

HDR Metrology™

Optoniks has developed the 3D HDR Metrology™ technology to overcome the issue of high-contrast ratio objects and surfaces in dimensional metrology.

- ContourPro 4D Distinguishing Characteristics:

- (Patent Protected)

-

- ▪ Non-Contact, Non-Coating and Non-Destructive Measurements

- ▪ 3D Shadow Removal

- ▪ Parallel Processing Metrology

- ▪ Film Layer Thickness with Scattering Material

- ▪ SGA & Warpage Solutions

- ▪ Thin layer PCB Warpage measurement

- ▪ Automated Inspection Capability for In-Line Quality Control

| Measurement Items |

|

| Field of View (FOV) |

|

| Z-Range |

|

| XY-resolution |

|

| Measurement Repeatability (Height) |

|

| Stand Alone System |

|

| Integration Module |

|